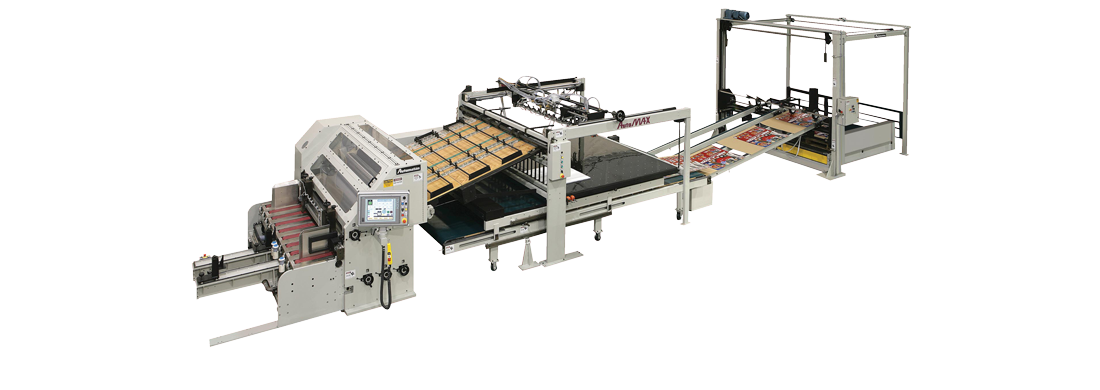

The AutoMAX Labeling/Laminating System is the most versatile in the world. It has the ability to singleface laminate, spot and full mount litho sheets to corrugated sheets, knocked-down boxes, and diecut sheets. The operator is able to accomplish quick setups with recipe job setup and also achieve precise registration (+/- .035” / .9mm) over a broad range of substrates and labels at speeds up to 6,000 sheets per hour with a fully automatic machine.

A 15” full-featured touch screen computer, singleface module, automatic corrugated upstacker up to 120” board, dual label/dual board, and heated water cleanup are all options available with the AutoMAX. The 15” full-featured touch screen computer has video playback capability and allows the operator to troubleshoot, review setups and assist in machine maintenance with the use of video clips displayed on main control panel. The singleface module is easily inserted or removed from the machine and allows the boxmaker to have a “dual function” laminator for both labeling and singleface laminating. This machine is designed with the user in mind.